Hemp fiber is one of the strongest natural fibers and is found in the hemp plant. The fiber is versatile and can be used in apparel and in building materials. The high demand for CBD and other hemp products has seemed to overshadow the real benefits to harvesting hemp for hemp fiber.

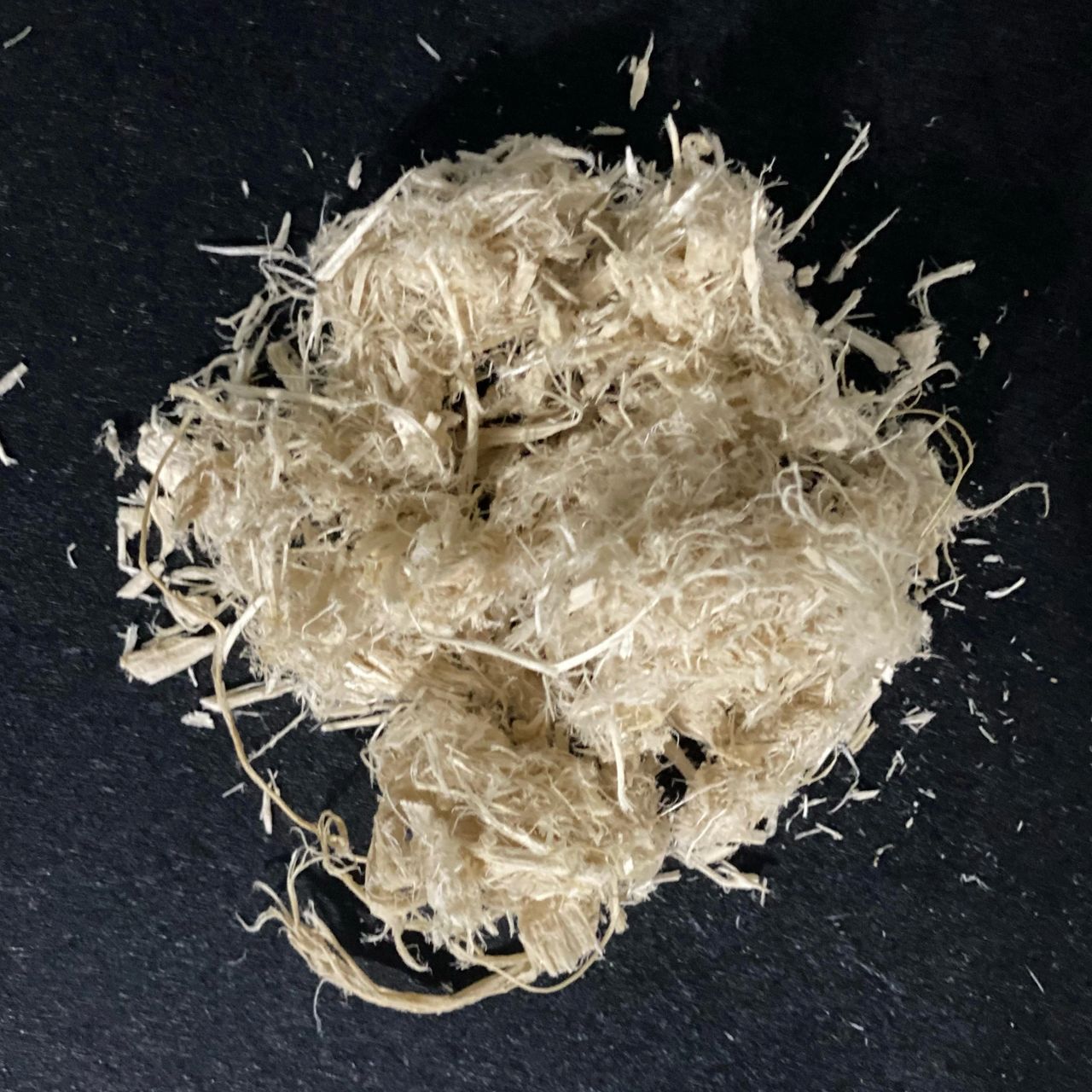

The stalks of a hemp plant are made from two layers; the outer layer is created from a rope-like bast fiber and the inner layer is made from a woody pith which is called the hurd; however, only the outer layer is used for the finished fiber product. The cording is stripped from the plant and has been used for years, even found on ancient maritime vessels for rigging sails – showing it’s strong, sustaining, durability. While the stalk fiber can be refined to varying degrees, it can feel like canvas or as delicate as cotton cloth. Advantages to hemp fiber is the breathable material that is resistant to mold and microbes and is light weight, as well as moisture repelling.

For the farmer, your crop is planted the same with our hemp seed. The simple plant that for the most part takes little effort to maintain and is sustainable in multiple weather patterns. Harvesting the plant and then retting the fibers in the field, which is separating them from the bark and naturally facilitates pectin removal through the exposure in the elements. This process takes between 4-6 weeks. Creating bales and using a hammermill helps separate the two layers. Next the separated fibers are carded into strands and cleaned for impurities before being moved to a manufacturer for steam explosion which renders the raw hemp into weavable fibrous material. When planting our hemp seed, your harvests will be more productive because it was bred to produce a greater amount of CBD while generating top notch fiber and hurd byproduct within the same plant. This means a farmer can utilize the whole plant.

Finished fiber has been used in clothing more recently, merchandizing on the “green” movement, but has also been used for upholstery, bedding, towels and other household items. The fiber and material are extremely absorbent and durable, which is one reason its popular for towels.

China and France currently lead the global market for hemp fiber, but with the U.S. finally getting on board with hemp production the U.S. market is on the upswing and starting to saturate the economy. This would seem incomprehensible to our founding father George Washington who once was a cultivator of industrial hemp.

The production of hemp fiber or fabric costs the same as growing cotton and switching products to hemp has very little cost additives. The process is simpler than harvesting cotton and that factor keeps prices low for manufacturers. The perk is the novelty of the product as it stands currently. Retailers are willing to pay a bit more due to the demand of hemp products. You can also have your fabrics certified by the Global Organic Textile Standard by having fabric that is at least 70% organic, which is easily met through the product alone. In the 2021 US Hemp Harvest survey it should the average price for hemp fiber leads all other hemp products produced at $1.50 per pound. The projected value of the hemp fiber market is 43.75 billion by 2027, increasing in growth by 33% from 2020 – 2027.

What does the future look like for hemp fiber? Currently there are large car companies investing in the product to help create light weight, eco-friendly cotton alternatives. BMW is using the products to reinforce door panels for higher safety standards. Feminine brands are looking into using the product for sanitary items, this is a market that will always be in high demand and enforcing an eco-friendly item is very sought-after. The possibilities will continue to evolve, but the U.S. agriculture has to step up to meet the demand.

Farmers, contact us today at 866-253-6733 to learn more or to purchase our miracle hemp seed which lowers risks and costs while increasing profits for hemp farmers.